CELEBRATING OVER 50 YEARS IN BUSINESS! LEARN MORE

CELEBRATING OVER 50 YEARS IN BUSINESS! LEARN MORE

Ohlinger Industries prides itself on being a one-stop shop. By keeping virtually all of the work in-house we are able to delivery quality parts with shorter lead times at a reduced cost. Ohlinger is committed to investing in new technologies to meet the needs of our customers. See our latest venture into Cold Spray technology.

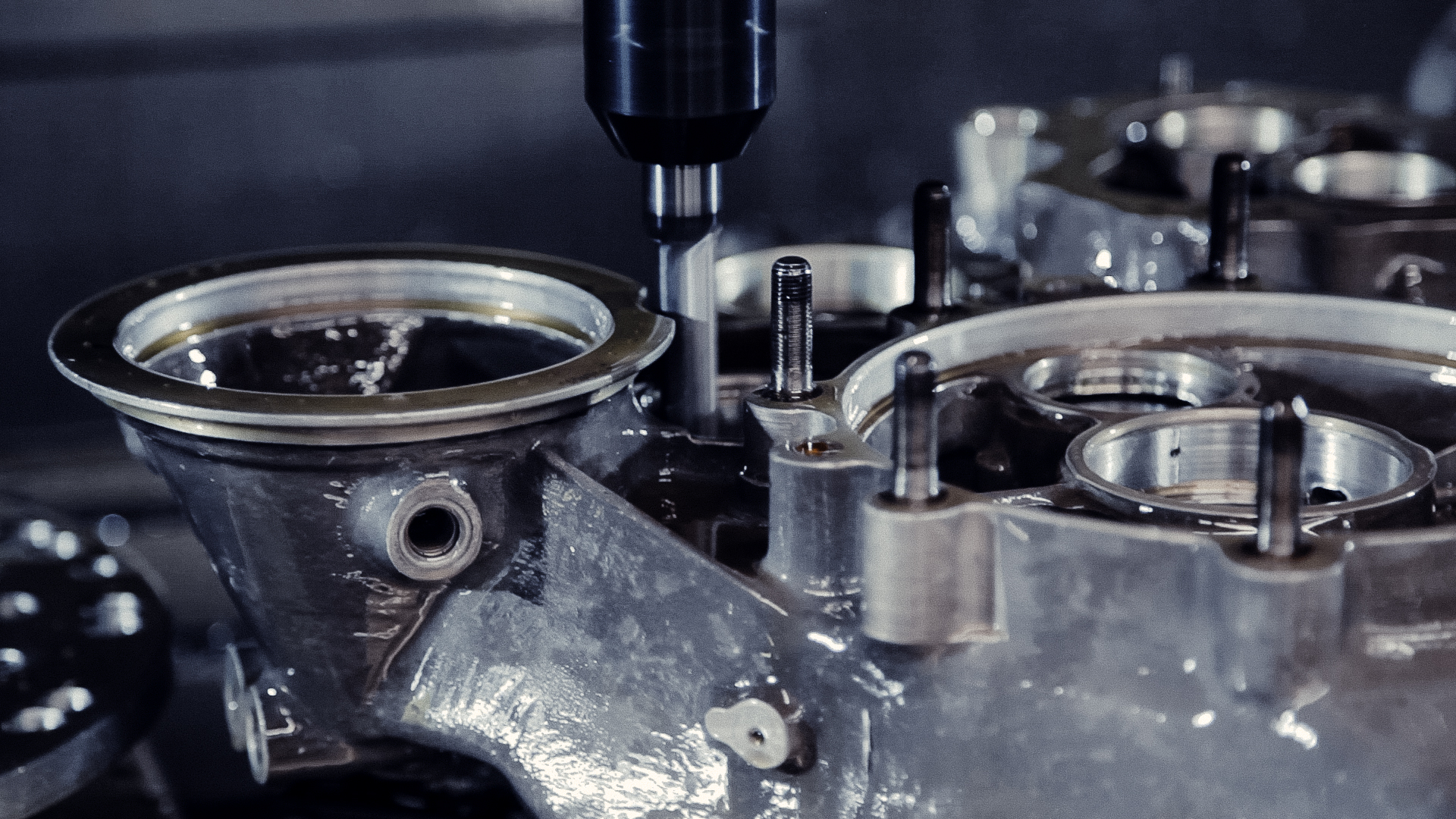

CNC Machining is one of our core competencies. We utilize the latest in machining technologies to maintain the highest quality standards while driving down overall cost.

Our full line of horizontal and vertical machining centers offers accuracy and repeatability enabled through probing, DNC and CAD systems; with a working envelope up to 84” x 32” x 30”

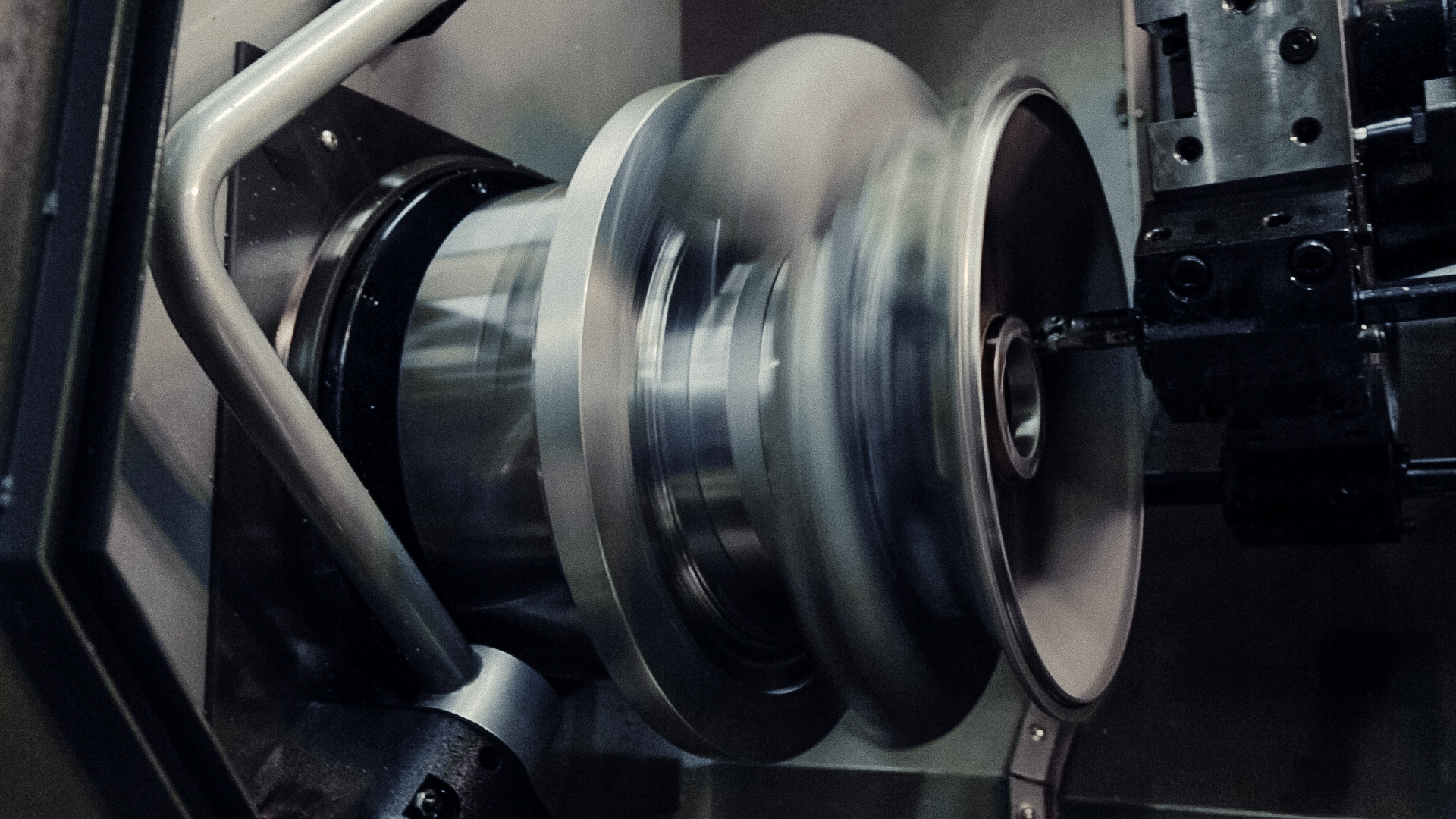

Ohlinger’s full range of turning centers has up to a 40” swing capacity. Our exceptional staff is well versed in the cutting of a wide variety of materials; from abradable plasma spray coatings to nickel based alloys.

CNC MILLING

CNC TURNING

Our in-house Metal and Cold Spray department provides value to our customers with reduced turn times at a reasonable price.

Metal/Cold Spray Uses:

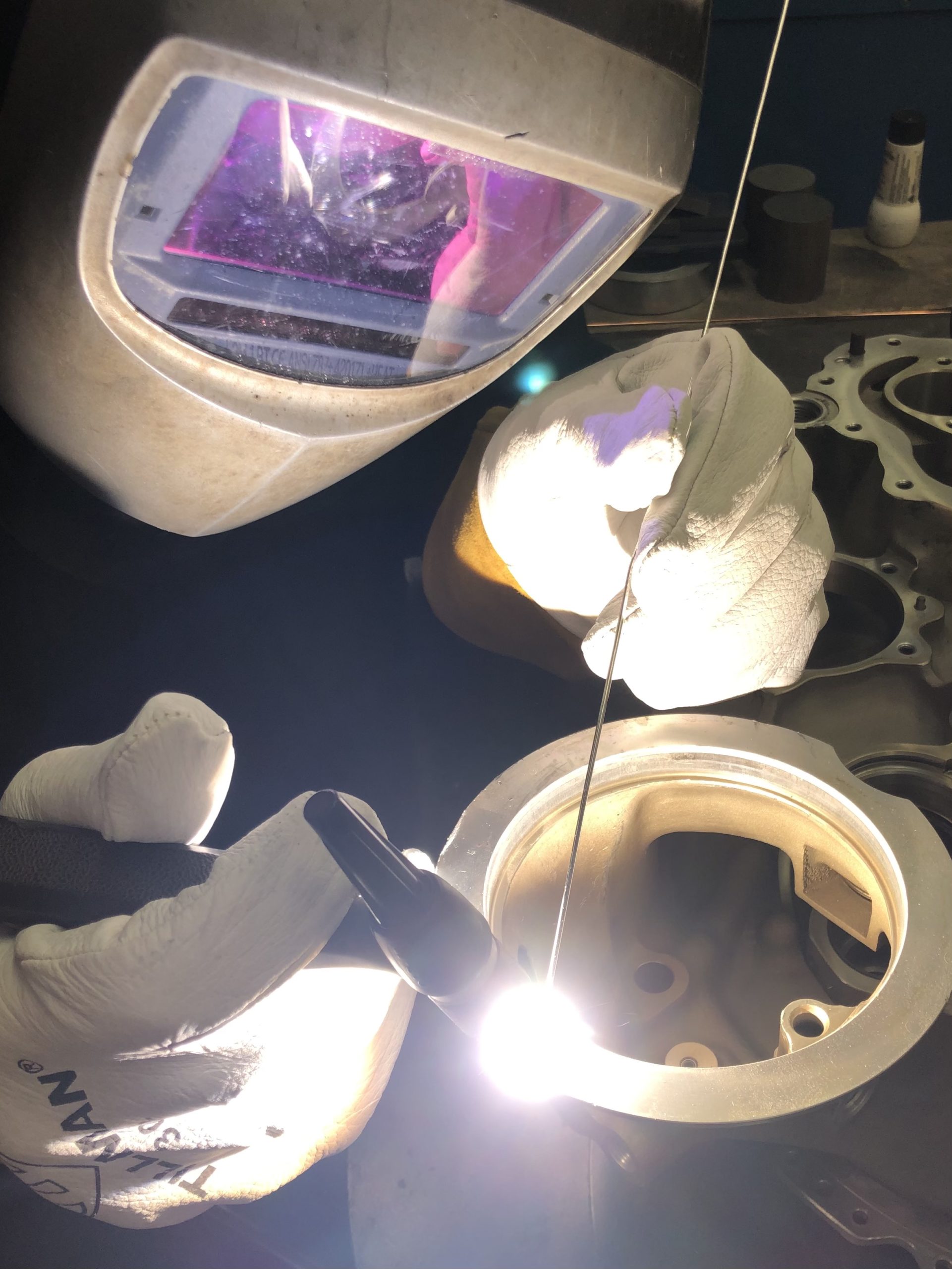

Ohlinger Industries provides welding on Aluminum, Magnesium, Steel and Heat Resistant Alloys, such as Titanium.

We have extensive experience in weld repair development for your Aluminum and Magnesium Components. Our certified welders use a Gas Tungsten Arc Welding process (TIG).

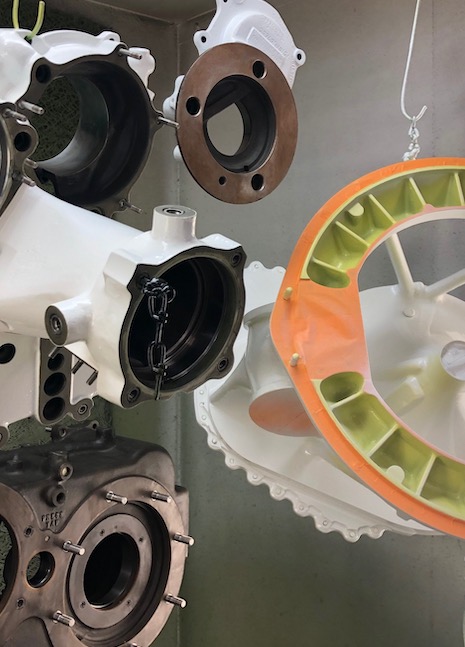

Ohlinger Industries services our customers with an in-house paint shop and chemical conversion coating department. Our chemical conversion processes treat Aluminum and Magnesium housings for corrosion protection.

We work to a wide range of specifications, from Military to OEM, to meet our customer’s requirements.

Not only do these departments support our repair facility, we offer fast turn around times for your spot operations.

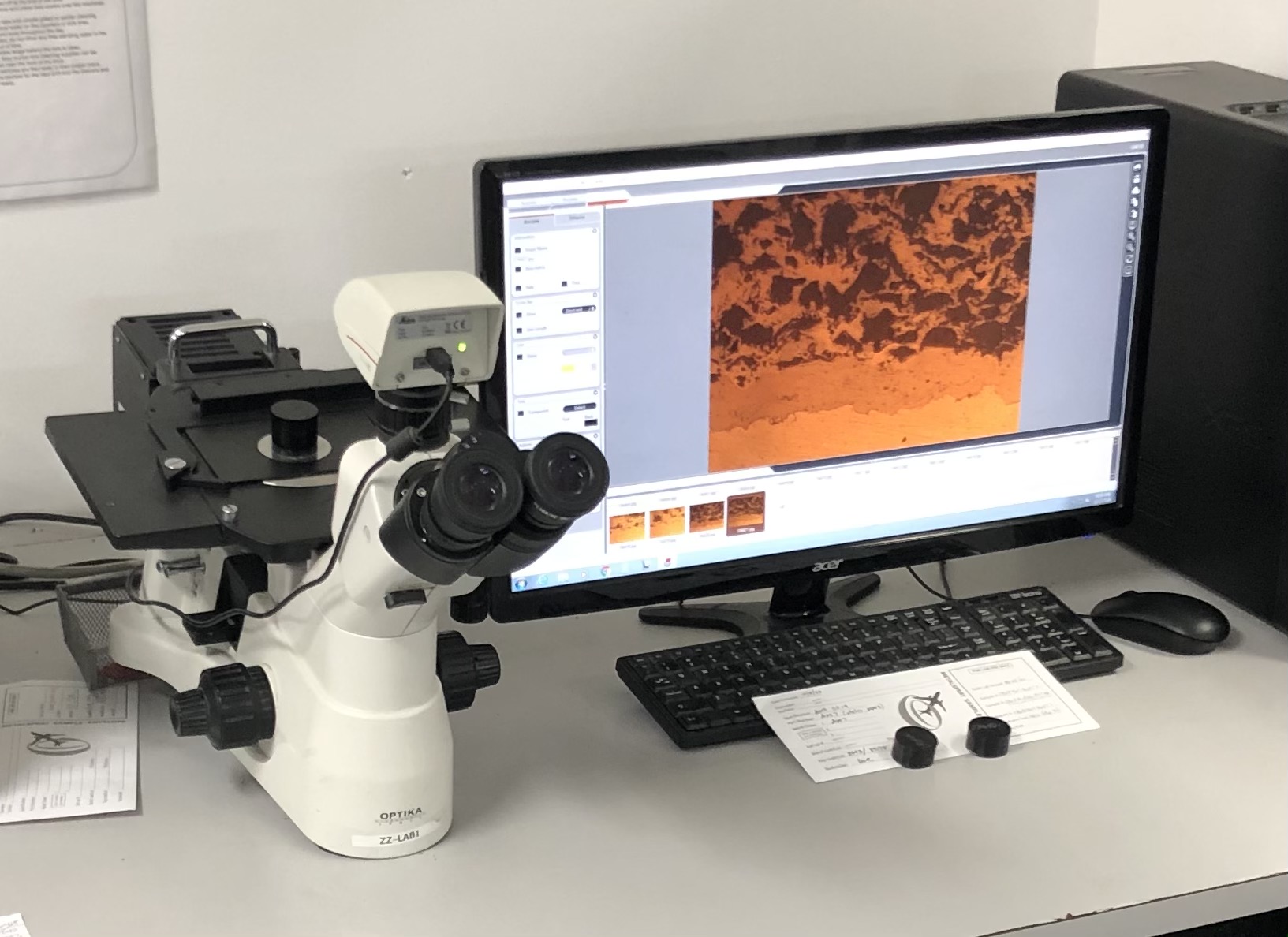

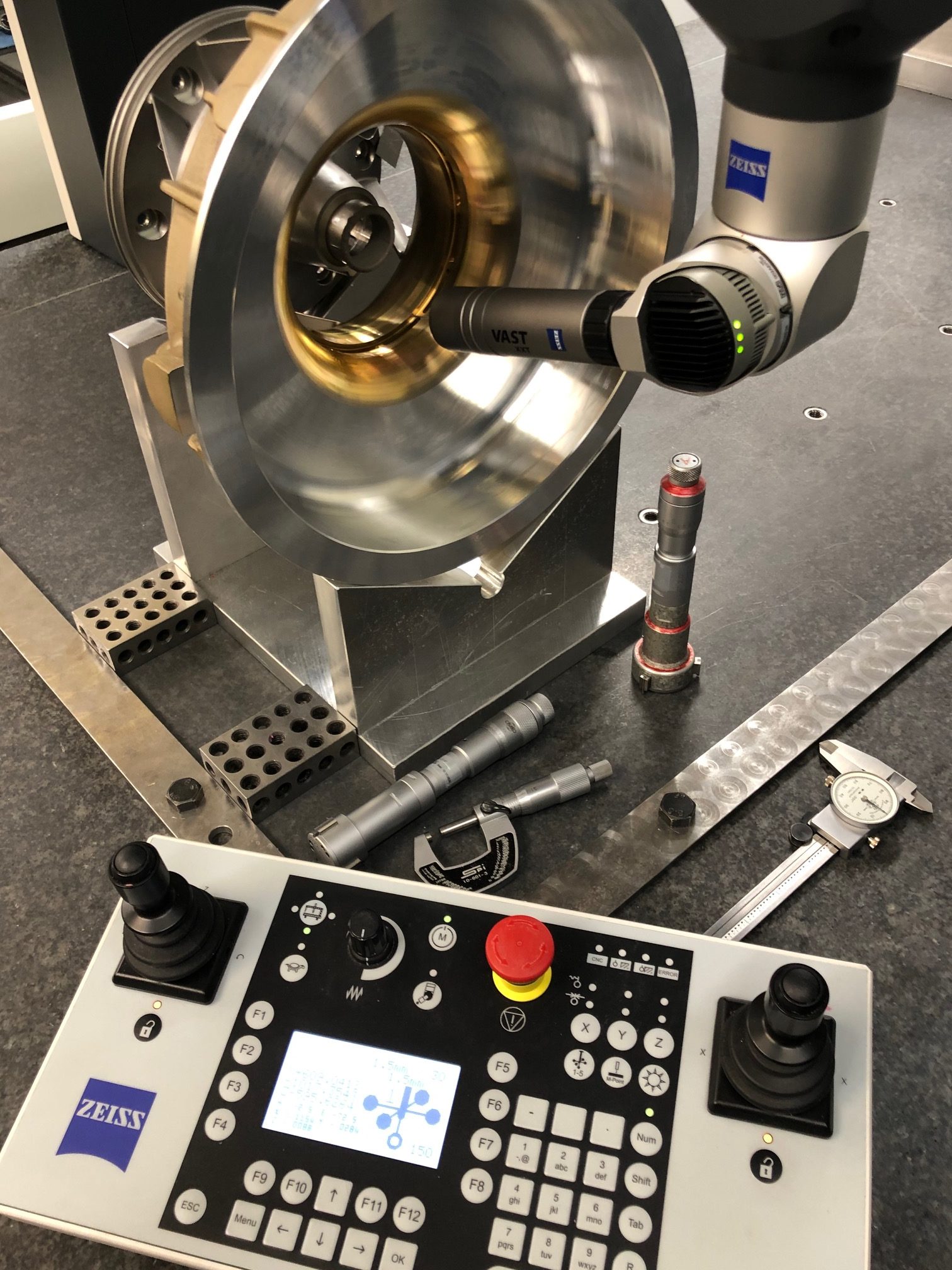

An AS9100 certified facility utilizing state of the art inspection equipment.

Inspection/Testing

Our professional engineering staff is ready to serve your needs from manual/service bulletin repairs to customer developed repairs. Our engineering staff uses the latest technology in repair development. A few of the types of repairs we develop are contour, diameter and surface restoration of magnesium and aluminum housings utilizing metal spray, cold spray and welding.

Get exceptional service life out of your gearbox with Ohlinger’s proven repair techniques. Our engineering staff takes pride in developing repairs that can be continually performed for the life of the gearbox.